Fundamentals of Simcenter 3D

- Duration: 2 Days

- Comprehensive introduction to Simcenter 3D, focusing on the foundational tools for structural and thermal analysis.

1. Overview of Simcenter 3D and its applications.

2. Navigating the interface and setting up projects.

3. Creating and managing simulation models.

4. Setting up boundary conditions and material properties.

5. Meshing techniques and refinement.

6. Performing structural and thermal analyses.

7. Post-processing and interpreting results.

8. Troubleshooting and best practices.

Simcenter 3D Non-linear Analysis

- Duration: 1 Day

- Detailed training on non-linear structural analysis, covering material and geometric non-linearities.

1. Introduction to non-linear analysis in Simcenter 3D.

2. Setting up material and geometric non-linearities.

3. Advanced boundary conditions and contact modeling.

4. Analyzing plasticity and creep effects.

5. Simulating residual stresses and large deformations.

6. Running and interpreting non-linear simulations.

7. Post-processing results for non-linear problems.

8. Case studies and troubleshooting.

Simcenter 3D Advanced Dynamics

- Duration: 1 Day

- Training on advanced dynamic simulations, including forced vibration and transient response analysis.

1. Introduction to advanced dynamic analysis techniques.

2. Setting up transient and forced vibration simulations.

3. Analyzing frequency response and PSD analysis.

4. Modeling shock loads and transient impacts.

5. Simulating coupled dynamic systems.

6. Post-processing dynamic results.

7. Case studies in advanced dynamics.

8. Troubleshooting and optimization.

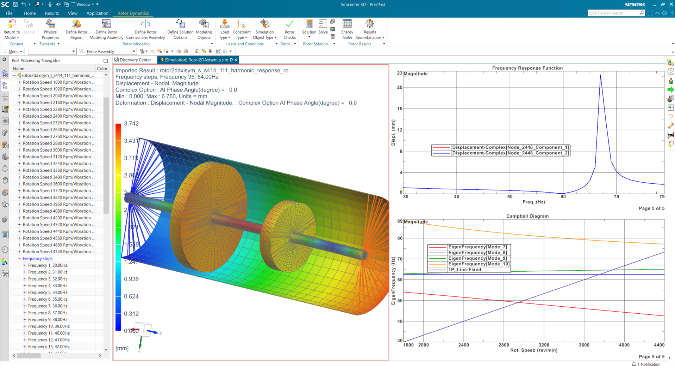

Simcenter 3D Rotor Dynamics

- Duration: 1 Day

- Focused training on rotor dynamics, gyroscopic effects, and Campbell diagrams.

1. Fundamentals of rotor dynamics and its applications.

2. Setting up gyroscopic effects in simulations.

3. Using Campbell diagrams for stability analysis.

4. Defining input parameters for stiffness and damping.

5. Running rotor dynamics simulations.

6. Post-processing results for rotor systems.

7. Case studies in aerospace and automotive industries.

8. Troubleshooting and tips for rotor dynamics.

Simcenter 3D Durability Prediction

- Duration: 1 Day

- Comprehensive training on lifespan prediction using fatigue analysis techniques.

1. Introduction to fatigue and lifespan prediction.

2. Setting up fatigue analysis in Simcenter 3D.

3. Modeling material fatigue properties.

4. Simulating load cycles and stress ranges.

5. Running lifespan prediction simulations.

6. Post-processing fatigue results.

7. Case studies in durability analysis.

8. Troubleshooting fatigue simulations.

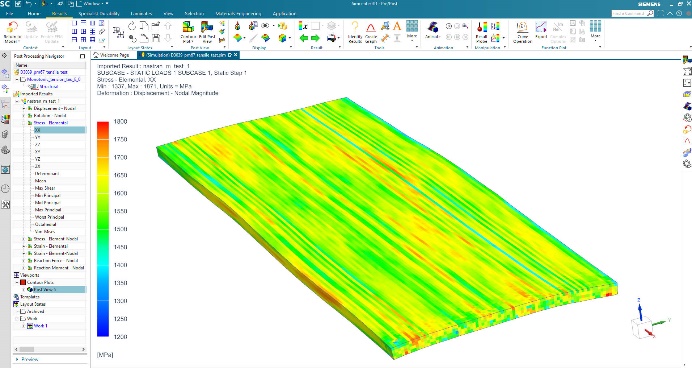

Simcenter 3D Composite Materials

- Duration: 1 Day

- Specialized training on composite material analysis for structural and dynamic loads.

1. Introduction to composite material analysis.

2. Setting up composite layups and materials.

3. Analyzing strength and dynamic responses.

4. Defining boundary conditions for composites.

5. Simulating thermal and structural behaviors.

6. Post-processing results for composites.

7. Case studies in aerospace and automotive applications.

8. Troubleshooting composite simulations.

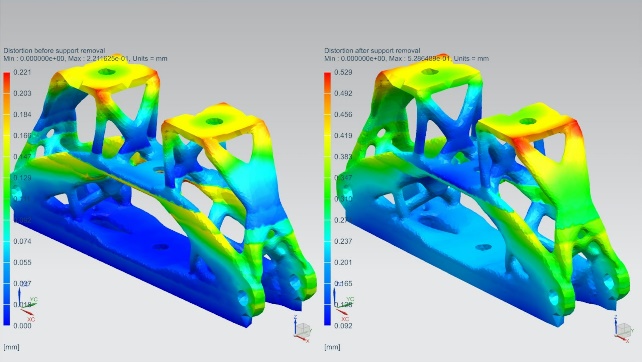

Simcenter 3D Additive Manufacturing

- Duration: 1 Day

- Focused training on additive manufacturing and topological optimization workflows.

1. Overview of additive manufacturing in Simcenter 3D.

2. Setting up simulations for 3D printing workflows.

3. Using topological optimization techniques.

4. Simulating residual stresses in printed parts.

5. Post-processing additive manufacturing results.

6. Case studies in industrial and consumer products.

7. Optimizing designs for additive manufacturing.

8. Troubleshooting and best practices.